Project: City Quays Belfast

Contractor: Tyrone Formwork

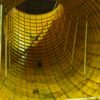

Scope: Special Formwork was approached by Tyrone Formwork to design, develop and engineer a circular column formwork system that was suitable for the in-situe casting of circular columns and also considered the site lifting requirements and construction schedule.

The 800mm diameter circular columns to be formed was of an architectural finish requirement with an average pour height of around 10 meters, the columns supplied by special formwork incorporated a low-level pump port, and therefore the columns were designed and supplied to be suitable for 10+ meters of pressure.

The pump port position was strategically placed so that any blemishes in finish fell below grading levels so that would not be seen on project completion.

In addition to this Special Formwork Design and manufacture concrete shut off valves and port plungers that push the concrete back to reduce any potential pour defects.

The main contractor had progressed well with construction, resulting in lifting traditional column formwork panels into position difficult as the over head crane was obstructed by permanent works steel work to enable the columns to be lifted into position.

To overcome this a C Hook Lifting frame was integrated into the columns as a bolt on fixture, this allowed the column panels could be positioned, using the already available overhead crane and reduced requirements for any additional lifting equipment.

To reduce the need for multiple lifts, and also any requirement for temp propping between placement of one panel and the next the column formwork was additionally hinged.

This allowed the columns to be lifted as a single unit, placed around the reinforcement and previously formed kicker in a single operation.

The C Hook Design additionally took into account the adjacent finished floor level allowing for the top of the column to be supported by the above finished floor resulting in a column design that did not require additional propping.

Overall multiple columns were supplied to enable a fast-paced schedule of construction, this with the additional features allowed for in the design stages created an overall column formwork system that delivered a great architectural finish and also aided the contractor in their construction approach, by limiting the number of lifting operations required and also removing requirements for separate lifting equipment.