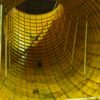

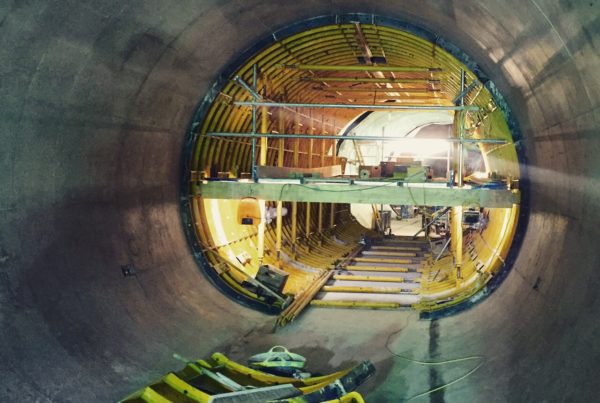

Special Formwork fully enjoyed the challenges this project brought from high uplift forces, to lifting an asymmetrical shape manufactured from man manageable formwork panels wrapped in 20 tonnes of reinforcement.

From all parties the project required collaboration and synchronized thinking both from the planning and design stages and onsite construction phase.

Overall shows how teamwork can conquer some awesome construction challenges

Some Interesting Project facts

1 900+ Designed Unique Parts

2 5000+ Manufactured Components

3 4000+ Laser Cut Profiles

4 400+ CNC Rolled Components

5 65 tonnes of Prime Steel Processed

6 90% of Material CNC Processed prior to manual fabrication

7 100+ Documents Generated

8 25+ Structural Analysis Reports using FEA

9 200+ Drawings Sheets

10 All Elements 3D Designed

11 Virtual Model Production Hrs = 468

12 Virtual Prototype Production hrs = 160+

13 Physical Manufacture Production Hrs = 2000+

14 Factory Assembly Production Hrs = 300+

15 4000+ Nuts & Bolts

16 Internal Full Design Check

17 External Cat 3 Design Check

18 Main Contractor Appointed Design Check

19 Fabricated and certified lift points to 20 Tonnes

20 10+ Client Meetings & Design Reviews

21 30m+ Below Surface Level Operation

22 Dual purpose for bend and straight shaft

23 Bend Volume = 195m³

24 Shaft Volume = 120m³

25 Bend Pour Volume = 330m³ +

26 Shaft Pour Volume = 300m³+

27 1280kn Uplift Force Restrained

28 1700 Horizontal Force Restrained

29 600Kg of Welding Wire Used

30 100 Litres + of Paint

31 Critical path on a 20+ Billion Project

32 2 Uses Extended to 4 due to Engineered Solution

32 99% recyclable